Yep! thats the good question!

1. draw cables from neutriks through a rubber gasket straight to ADI2pro/uscx2. Cheapest and probably the best solution not to disturb any signal.

2. I have standard DB-9 and Neutriks for one component(RME box) at home. a total of €50 for the rest. Its alredy in the mail.

This just follows the idea of RME using the DB-9 as a prpprietray connector bcs low real estate at back of "9,5 boxes. A continuum of RME design.

3. The high end solution to maintain 75ohm impedance through connections. €200 - 300 for complete interconnect plus internals. Hassle to get the recommended cable so I will have to split the weborder. No way Im gonna buy a crimping tool for this(have you seen pricing).

So the answer to your question:

I want a sleek solution for my piece of furniture. It has to maintain the signal. It has to look good, thought through and be 100% functional. Satisfy my soldering urges.

I think I have already put away the idea of special coax connectors. Im sure it would have worked nice, but maybe not a mentally sound solution, and certainely not economical. There is just not enough return for money except fancy contacts and party conversation starter. Money is just needed elsewhere.

You are a professional so the quickest route from a - b probably makes most sense. I do this as a hobby,

---------------

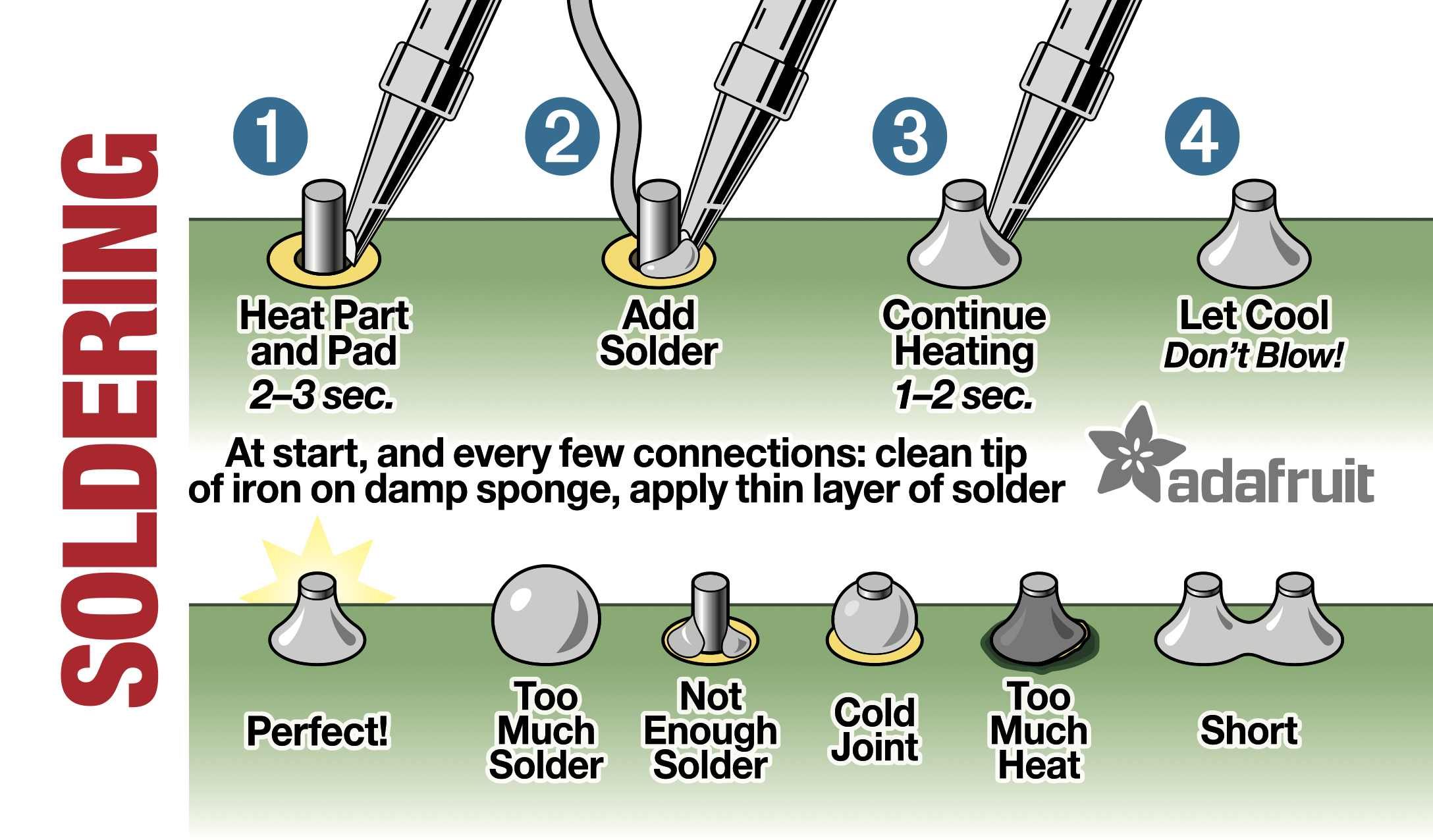

I bought the indium and bismuth solder for difficult contacts. At first try I did a perfect pentaconn. Paste flux also helped. For a solderpot I would just put in a piece of Sn/Ag, heat, reheat and put in the wire. If I really wanted to tap myself on the shoulder it would be for mastering those damned laquered headphone wires, I had to wait for the world to invent internet to fix those.

About gold I looked up spec for a Neutrik XLR. Its a 0.2 micron layer so its well below the 1.5 micron there problems are supposed to arise. The thing about gold is that no one tosses it around, its as expensive as it has ever been. So there are very strong reasons to specify it precisely for different needs. A quick search gave me a DB contact with 2.5 micron for whoever would need that. With these thicknesses gold recovery makes perfect sense. Audio contacts are basic soldering, but there are just mountains of information on how to specify any solder joint for whatever need. All the way to aerospace.

As my project proceeds I will put up some images at ASR, and youll be sure to know then its done.

Thanx for sound advice Kais, and earthing my spinning erdnuss

ADI-2 DAC, ADI-2 PRO, DigifaceUSB, UCXII, ARC, HEGEL.h80, KEF.ls50, HD650, ie400pro _,.\''/.,_